Home ≫Ultra Low Temp. >Deep Freezer -86°C >Cascade ULT Freezer SMI-165EJ-397

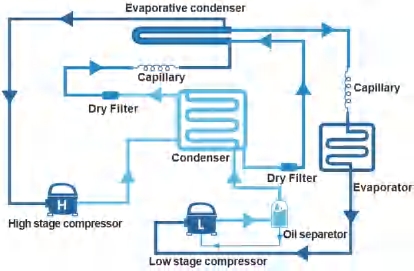

The Ultra-Low Deep Freezer SMI-165EJ-397 functions as a laboratory freezer, ultra-low medical freezer, and deep freezer. It is suitable for use in hospitals, health and disease prevention systems, research institutions, universities, the electronics industry, biotechnology facilities, military enterprises, deep-sea fishing companies, and various laboratories. The Jindal ULT freezer features a two-stage cascade cooling system utilizing absolute hydrocarbon refrigerants, R290 and R170, as natural gases. Its inverter compressors are programmed to enhance energy efficiency during long-term preservation and ensure rapid temperature recovery when the door is frequently opened, maintaining specimen viability.

High-efficiency frequency conversion compressors automatically adjust operating power based on the heat load, making the equipment energy-efficient.

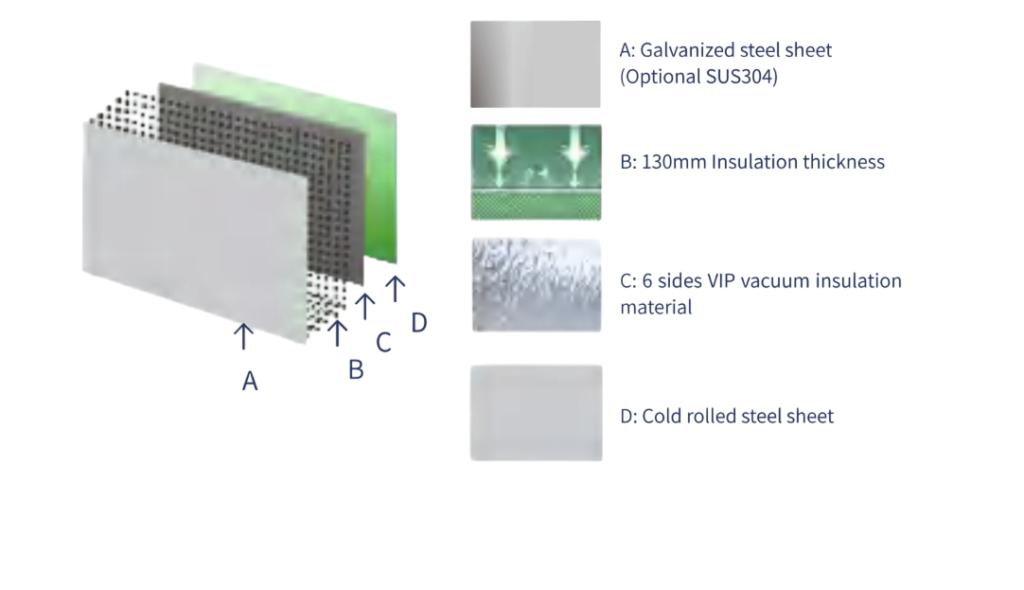

The combination of 130mm CFC-free PU foam and high-quality vacuum insulated panels provides superior insulation, preventing rapid temperature increases and ensuring low energy consumption.

The ULT freezer uses natural green gases as refrigerants to meet safety requirements for usage. These natural hydrocarbon refrigerants are SNAP-compliant according to U.S. regulations. Additionally, this is supported by European Union regulation (EU-517/2014). The foaming agents used during manufacturing are fully controlled to ensure they are environmentally friendly.

The intelligent control of the inverter compressor optimizes its running speed based on the conditions. When the inverter compressor is operating normally, it runs for longer periods than a conventional compressor but at a minimal speed. This reduces power consumption and helps maintain a stable freezer temperature. When the door is opened, the compressor adjusts its speed to quickly bring the temperature inside the freezer back down to the set value before resuming its normal cycle.

The cascade system consists of two independent refrigeration cycles: a low-stage cycle and a high-stage cycle. These cycles are connected through a cascade condenser. The high-stage and low-stage systems operate separately using different refrigerants, with the evaporator of the first cycle cooling the condenser of the second cycle. The first stage lowers the temperature to -40°C, while the second stage further reduces it to -86°C using natural refrigerants.

Model No. | SMI-165EJ-397 |

Capacity(L) | 397 |

Internal size(W X D X H)mm/Inch | 440 X 696 X 1266/ 17.32 X 27.4 X 49.84 |

External size(W X D X H)mm/Inch | 785 X 1041 X 1947/ 30.91 X 40.98 X 76.65 |

Package size(W X D X H)mm/Inch | 890 X 1165 X 2158/ 35.04 X 45.87 X 84.96 |

NW/GW(Kgs) | 237/314 (wood packing) |

Temperature range | -40 to -86℃ |

Ambient temperature | 16-32℃ |

Cooling performance | -86℃ |

Climate class | N |

Controller | Microprocessor |

Display | 10‘’HD Intelligent touch screen |

Compressor | 2Nos. |

Cooling method | Direct cooling |

Defrost mode | Manual |

Refrigerant | High stage: R290, Low stage: R170 |

Insulation thickness(mm) | L/R:130,B:130 |

External material | Cold rolled steel |

Inner material | Stainless steel |

Shelves | 3(stainless steel) |

Access port | 2pc. Ø 25 mm |

Casters | 4+(2 leveling feet) |

Data Logging/Interval/Memory capacity | USB/Record every 5 minutes / 10 years |

Backup battery | Yes |

Temperature | High/Low temperature, High ambient temperature |

Electrical | Power failure , Low battery, Battery power detection failure |

System | Sensor failure, Communication error, Condenser overheating, Door ajar |

Freezer rack model | ZKML304-552B-CT |

Freezer rack/box (quantity) | 12/300 |

Product Brochure Link here