Home ≫Clean Air > Laminar Air Flow Cabinet >Horizontal Laminar Air Flow Cabinet (New Modular Design) SMI-156AH

Jindal designs equipment that accommodates advancement for: Improved Safety Conditions; Improved Productivity; Improved Quality and Reliability; and Reduction of Arm, Shoulder, and Neck Strain contributing to common workplace injuries.

Ergonomic designed equipment improves productivity, quality, and reliability. Expanded vision zone, large work area, proper lighting for reduced glare, forearm support for comfort and safety, and maximum knee/thigh clearance are just a few of the many ergonomic features designed into each Jindal product.

We offer a comprehensive range of high performance horizontal, vertical Laminar Flow Clean Air Cabinets. It has a modular construction, combining aesthetic appeal with functional utility and efficiency. These are designed to meet the filtration, illumination, noise & vibration requirements, providing air to meet class 100 (class I) conditions, to the extent applicable.

These laminar Flow configurations find extensive application in Scientific, Medical and Industrial application where a localized high quality clean working environment is essential. These are designed to provide an atmosphere free from airborne particles with laminar air flow on the work table. These are also ideal for microbiological manipulations, work with bioassays sterility testing & research work, vial filling & bunging operation in parenteral units & for general dry-processing work in semiconductor industry etc.

It provides a comfortable ‘sit down’ working position for the operator.

True Laminar Airflow

Unidirectional airflow moving along parallel flow lines at a constant velocity minimizes air turbulence within the work area.

Optimum Volume Of Air Creates A Safe Environment

Selection of specific motor/blower, HEPA filter(s), materials, electronics, work space and plenum sizes – creates a crucial combination of elements providing an optimal air volume for personnel, product, and environmental protection.

Experience Ergonomics

Ergo: “Work” Nomos: “The Study or Laws of….” Combines to mean: “The Laws of Work”

All Laminar Flow Clean Air cabinets are basically constructed with an outer body of Mild Steel duly powder coated. The inner work table is made of stainless steel. The side panels have windows of thick acrylic for viewing purposes.

The front of the cabinet is provided with a transparent sliding acrylic door which is very easy to use. The work surface of the cabinet consists of three valves for gas, air & vacuum line.

The Laminar Flow principle involves double filtration of air. Atmospheric air is drawn through pre filter and is made to pass through highly effective HEPA (High Efficiency Particulate Air) filters having efficiency rating as high as 99.99% with cold DOP and 99.97% with hot DOP, thus retaining all airborne particles of size 0.3 micron and larger. Double filtered air blows in laminar flow through the work table at designed velocity of 70 FPM-110FPM(Avg. Air flow velocity 90 FPM)

Blower Motor Assembly: –

Duly balanced, direct drive highly efficient centrifugal blower units sized to provide adequate air flow volume over the entire surface of HEPA filter. These are directly coupled to an inbuilt motor and operate with minimum noise level i.e. lower than 65 db on scale and Vibration less than 2.5 um.

Lighting: –

The work area is properly illuminated by diffused, glare free fluorescent light.

UV Germicidal Lamp: –

An in-built UV germicidal lamp helps in killing of bacteria and other microorganisms.

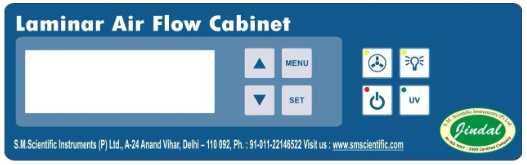

Fully Automatic Microprocessor control : –

A fully automatic dedicated microprocessor helps in monitoring all the functions of the Laminar Air flow Cabinet.

The advanced microprocessor monitors the air flow in real time to prevent sample contamination. A high quality membrane keypad permits control settings and access to default settings. The bright LEDs display the ON/OFF for blower operation, UV germicidal light, Fluorescent light, and Mains. A high quality air velocity sensor helps in sensing the actual air flow in FPM. This microprocessor warns of any deviations in the air velocity from normal velocities.

A bright LCD displays all the parameters including date, time, air velocity and timer. An inbuilt UV timer helps in the decontamination by switching ON the UV tube for a certain interval of time. A user friendly software and soft touch controls for blower, light, UV and power are easy to use.

Power Requirement: –

The instrument is designed to operate on 220V AC Supply.

Optional Accessories: –

Spare Accessories:–

Horizontal Model | SMI-156AH2 | SMI-156AH3 | SMI-156AH4 | SMI-156AH6 | SMI-156AH8 |

Working Area | 2’ X 2’ X 2′ | 3’ X 2’ X 2′ | 4’ X 2’ X 2′ | 6’ X 2’ X 2′ | 8’ X 2’ X 2′ |

Size of HEPA filter | 2’ X 2’ X 6” | 3’ X 2’ X 6” | 4’ X 2’ X 6” | 3’ X 2’ X 6” | 4’ X 2’ X 6” |

No. of HEPA filters | 1 | 1 | 1 | 2 | 2 |

No. of Pre filters | 1 | 2 | 2 | 3 | 4 |

Illumination | 1 X 20 W | 1 X 20 W | 2 X 40 W | 2 X 40 W | 4 X 40 W |

Custom built sizes as per the customer’s requirement can also be manufactured on request.

Product Brochure Link here