Home ≫Sterilization >Disinfectors >Washer Disinfector SMI-107A

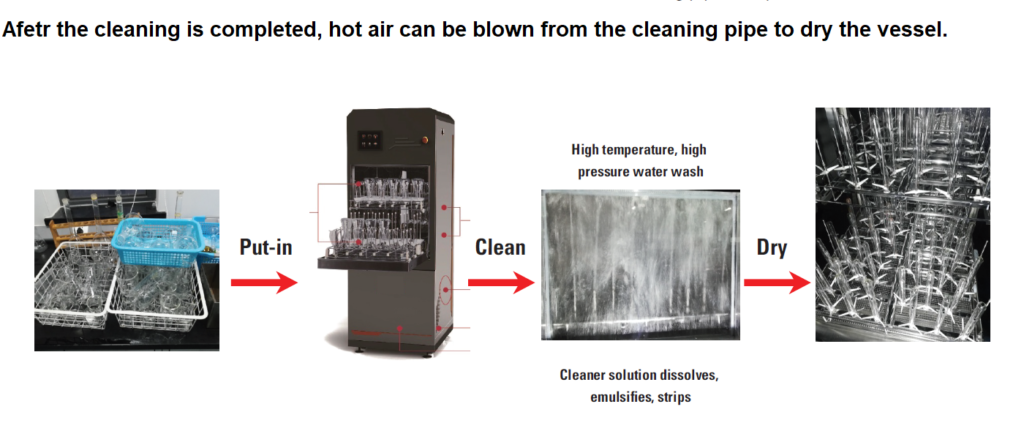

Washer disinfector is also called Lab automatic glassware washer. The whole process is water info spray scouring, washing with cleaner, cleaning, heating, drainage, drying, etc., and all are automatically carried out. As long as the program is set up, the intermediate process does not require any manual operation. After the vessel is placed in the automatic cleaning, the vessel can be used normally. Washer insulated with synthetic rubber based closed cell foam to guard against heat lost and reduce noise levels creating lower utility costs and a better user experience in the lab.

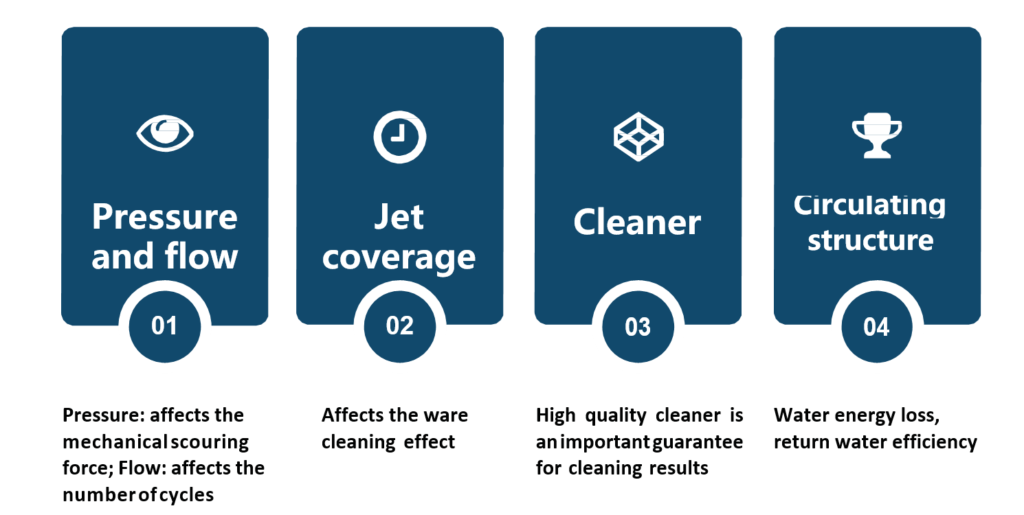

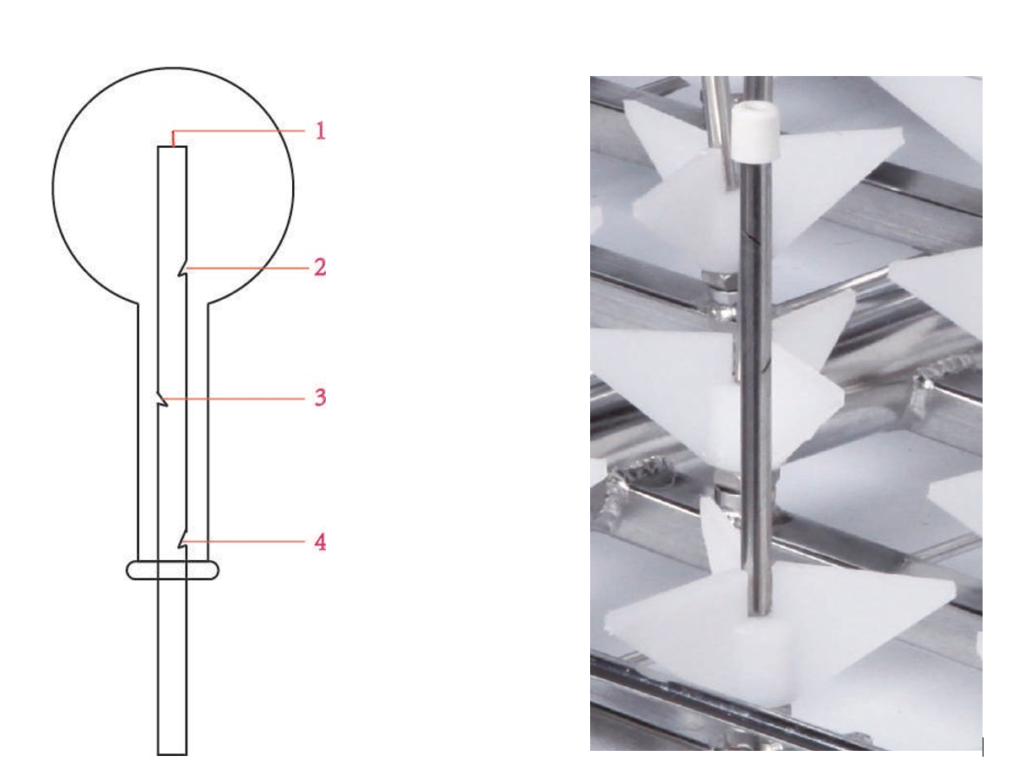

The inner and outer surfaces of various types of vessels in the laboratory are sprayed and washed by the mechanical scouring force of the high temperature and high-pressure water in the cleaning chamber. At the same time, combined with the cleaner to dissolve, emulsify and peel off the contents of the vessel, thereby achieving clean cleaning of the inner and outer surfaces of the vessel.

After the cleaning is completed forced hot air dryer system can be blown from the cleaning pipe to dry the vessel.

The machine is incorporated with an automatic detergent dozing system to doze the required amount of detergent in the rinsing water.

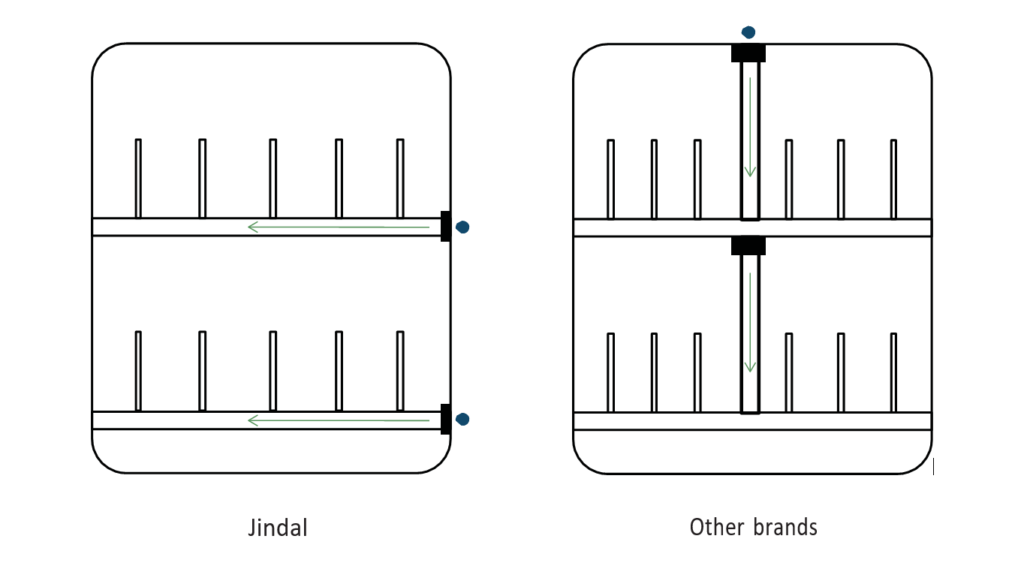

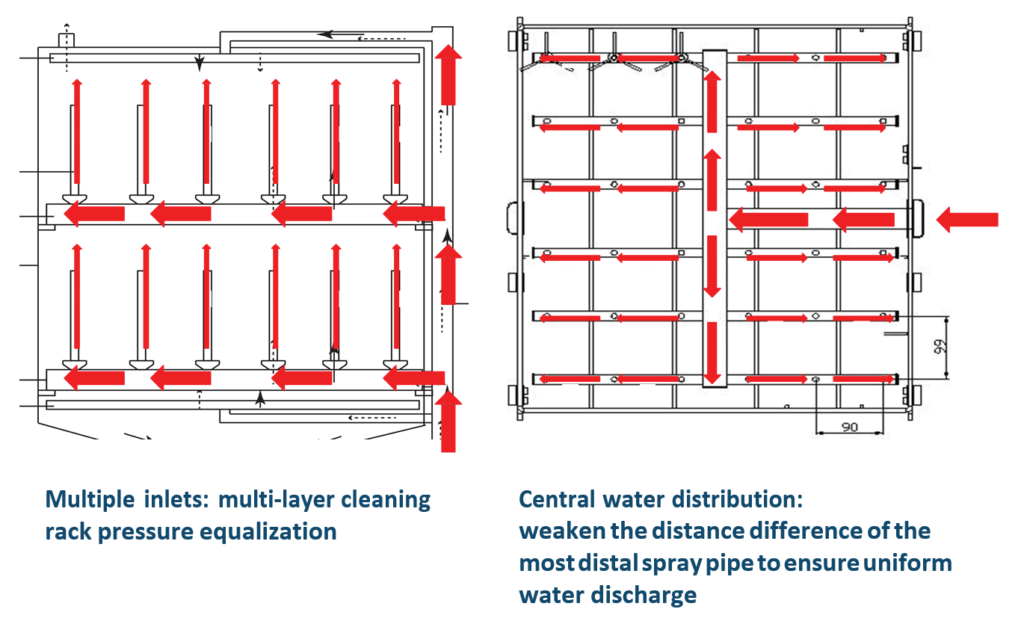

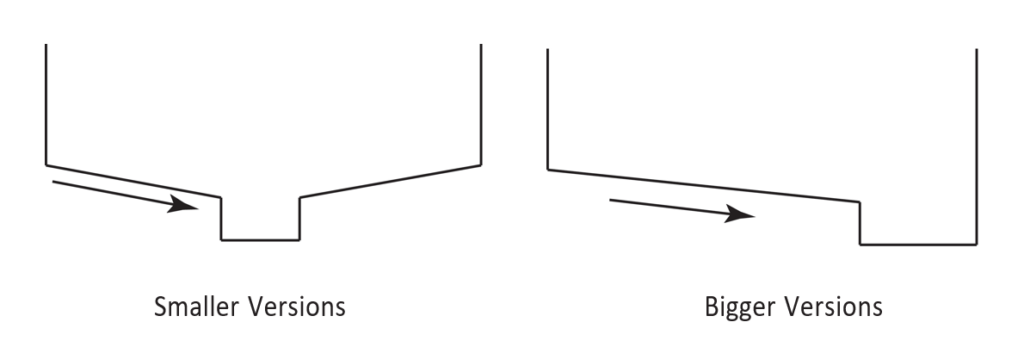

Fluid Mechanics: Fluid enters the farthest end without obstruction

Interchangeable rack multi-way water, central water distribution design!

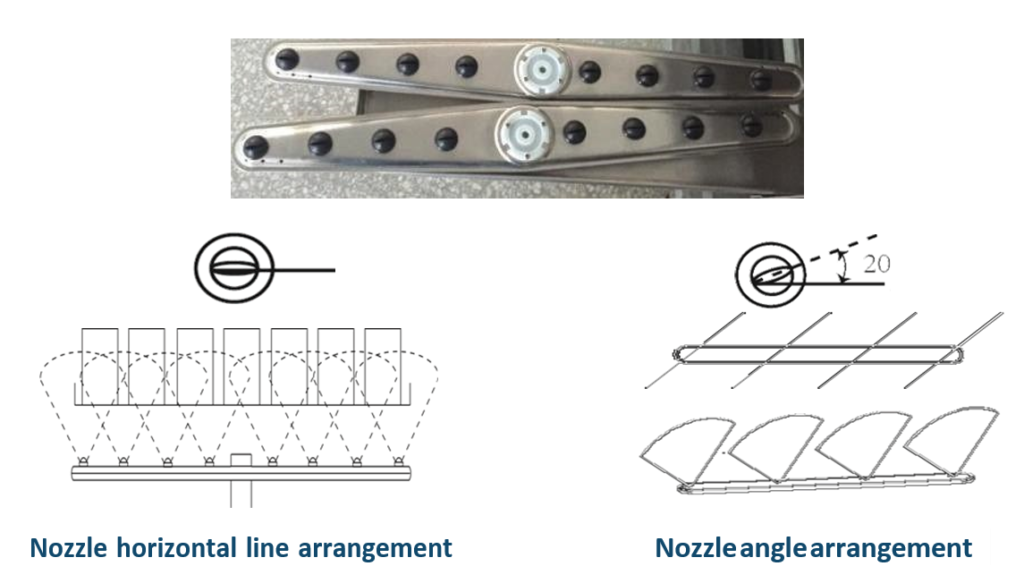

360° jet spray tube fan-shaped slit design

The special washing liquid for laboratory machine washing is suitable for cleaning most pollutants and can be discharged directly without pollution.

The effect of the cleaner on the cleaning is equivalent to the cleaning solution for the washing machine. The use of reliable and excellent cleaning aids is the key to laboratory cleaning. Accurate and repeated intake of cleaning chemicals by automatic peristaltic dosing pumps.

We use imported famous brands Alkali cleaner & acid cleaner. This ensures guaranteed product quality & stable performance. The cleaners have EU & US certification.

Conventional combination: cleaning conventional contaminants Powerful combination: heavy oil, heavy metals, etc. Hand immersion.

The disinfector consists of three rotary spray arms. The design and location of the arms ensure that every surface of the loaded material is uniformly cleaned. The chamber of the disinfector has rounded corners to prevent dirty breeding grounds. The rotation of the arm is activated by the water pressure which eliminates any mechanical drive system.

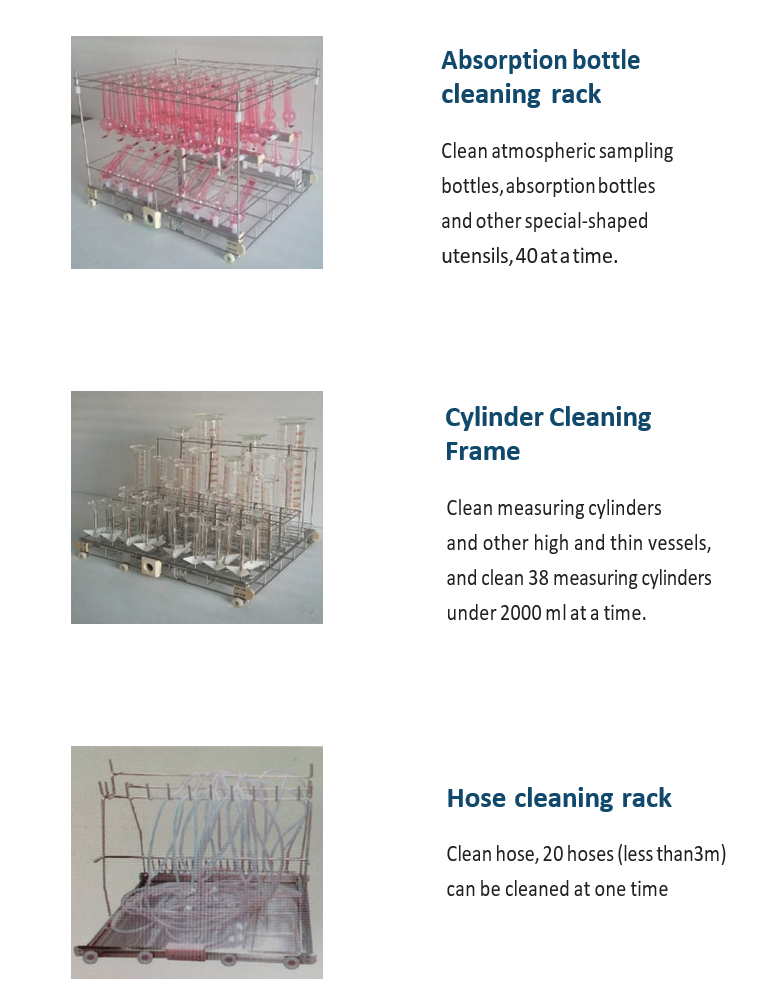

Our disinfector comes with a range of standard accessories for different surgical appliance & kidney trays, bottles, tubings & instruments.

The machine is incorporated with an automatic detergent dozing system to doze the required amount of detergent in the rinsing water.

The unit is incorporated with an in built electric water heater. The hot water here is used to disinfect the loaded material at a washing up to 95°C thermal disinfection after thorough cleaning & rinsing.

The disinfector has a microprocessor controls with self-diagnostic software and alarms. The operating console is provided with a electronic unit having LED for easy operation and monitoring of the process. 20 pre-programmed processes give the user fantastic for cleaning and disinfecting a wide range of load confirm.

As in hospitals, where hot water is not available, the disinfector is equipped with an electric heating system. Power supply is 240V,50 Hz with single phase.

The outer body is fabricated out of non-corrosive 304 Grade Stainless steel/PVC Molded. The Fold-down door made of solid 304L stainless steel. The door is viewing of the Inside chamber while in washing mode. All piping and valves are of Stainless-steel construction. Integrated automatic door locking system- prevents door opening during active cycles and protects the user from heat and chemical exposure.

The disinfector is a simple easy to use machine. The machine requires no installation. It has to be connected to the different supply lines and the drain line to start the operation.

Model No.: | SMI-107A |

Capacity | 200L |

Water Consumption/Cycle | 12L |

Inlet Water Pressure | 0.03 to 0.8Mpa |

Noise | <65dB |

Material | Robust High-Grade Stainless Steel 304 |

Electrical power | 7 KW |

Power Consumption Water Washing | 1.5 KW |

Power Consumption Water Heating | 15 KW |

Power Consumption Drying | 3.6 KW |

Power Supply | 380V, 50Hz (Standard); 110V, 60Hz (Optional) |

Washing chamber Size (W X D X H) mm | 610 X 745 X 855 |

External Size (W X D X H) mm |

|

Package Size (W X D X H) mm | 1200 X 1000 X 2200 |

Weight (Kg) | 90 |

Product Brochure Link here